Mould changing trolleys transport small injection moulds or deep-drawing moulds with weights ranging from a few hundred kilograms to tens of tonnes. The decisive moment here is when the mould is removed from or inserted into the machine. Here, the mould must be positioned very precisely - the risk of a collision with the machine is great and injuries to the operator can occur. With conventional tool change trolleys, positioning is usually realised with roller conveyors or ball tables. The disadvantage: the heavy loads move uncontrolled.

Mould changing trolleys transport small injection moulds or deep-drawing moulds with weights ranging from a few hundred kilograms to tens of tonnes. The decisive moment here is when the mould is removed from or inserted into the machine. Here, the mould must be positioned very precisely - the risk of a collision with the machine is great and injuries to the operator can occur. With conventional tool change trolleys, positioning is usually realised with roller conveyors or ball tables. The disadvantage: the heavy loads move uncontrolled.

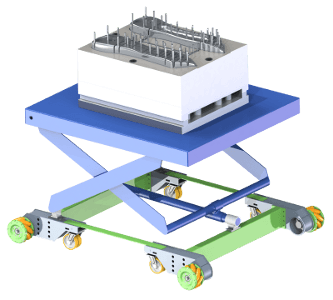

With an area-moving Mecanum undercarriage, positioning can be done with millimetre precision via joystick. This does not require any complex additional axes of movement on the trolley, but the vehicle itself is capable of fine positioning of the trolley.

The modular system "DONKEYmotion" makes it possible to build individual tool change trolleys in the simplest way. The drive units called "MecanumDrive" are compact wheel hub drives consisting of Mecanum wheels, motor and holding brake. The MecanumDrives can be flanged very flexibly to the base frame of the trolley. The system components "MecanumPowerBox", "MecanumBrain", the battery and other optional accessories, can be wired in plug-and-play fashion with the cable sets supplied. The control system already has powerful current outputs ready to control additional electric axes on the tool change trolley, such as a lifting table or swivel axes. The tool changing trolley is controlled via the safety PLC and radio remote control from the DonkeyMotion modular system or the wired operating panel.

In complex parking situations of the tool change trolley, it can move the last few metres exactly by itself with optical guidance. As soon as the sensor has detected the guide track, the tool change trolley moves quickly and with millimetre-accuracy to its target position.

Tool change carts with Mecanum wheels reduce the unproductive set-up times of your machines and thus save you money!

Ask us. We will be happy to advise you on the selection of our system components. We can also implement your complete tool changing trolley, just as you wish. Whether only the planning or the turnkey tool change system, you decide on the scope of our services!