Driverless Transport Systems for Modern Intralogistics

Universal AGV System for Intralogistics

The CALL THE DONKEY automated guided vehicle (AGV) automates a wide range of intralogistical transport tasks - and does so extremely flexibly! After almost 100 years of "sole dominance of the forklift truck", a transcending solution for intralogistical tasks is also offered for medium-sized and smaller companies.

With CALL THE DONKEY, the smart solution from the DONKEYmotion modular system product range, this type of intralogistics can be integrated easily and quickly.

Here, the driverless CALL THE DONKEY system convinces with great time and cost savings. Internal material flows in manufacturing and trading companies are made fit for the demands of Industry 4.0 by means of the conveyor system and supporting information systems.

Driverless transport system for high-speed starters

Whereas the introduction of driverless transport systems (AGVs) has so far failed due to the high effort involved in installation, CALL THE DONKEY opens up new possibilities in intralogistics.

CALL THE DONKEY is optimised for fast commissioning and flexible handling. Companies benefit immediately from the sophisticated logistics automation and can start directly with their individual production.

Thanks to the CALL THE DONKEY system, all the prerequisites for variable and variant-rich production are fulfilled. This is a great opportunity to make your own intralogistics more economical, thus remaining competitive and strengthening your own market position.

CALL THE DONKEY - driverless transport solution for flexible intralogistics

The standardised modular system components allow the automated guided vehicle system to be quickly scaled and adapted to your intralogistics needs. The adjustment to fluctuating production capacity utilisation in intralogistics is absorbed. Nothing stands in the way of maximum economic production!

Intelligent and economical automation of intralogistics

In intralogistics, CALL THE DONKEY relieves employees of strenuous and time-consuming material movements - they can concentrate on their core competences again. Your employees can continue to decide for themselves which goods are to go where and when, by entering the desired transport orders on portable devices. The simple and intuitive control of the automated guided vehicle makes it easy to handle. Even if the production environment is complex - the employees can be relied on. They know the process and make good and correct decisions about necessary material movements in a fraction of a second.

The control system with extensive "machine-to-machine interfaces" is ready for Industry 4.0. CALL THE DONKEY communicates with your products, production machines or PPS systems.

INCREDIBLY STRONG - DONKEY features

- Quick commissioning

- Manageable by the operator: changes to the route model, new stations and more autonomy possible

- High cost-effectiveness - 80% of typical intralogistical transport tasks are covered with standard modules

- High investment security and short amortisation, as individual modules can be added as required

CALL THE DONKEY modules

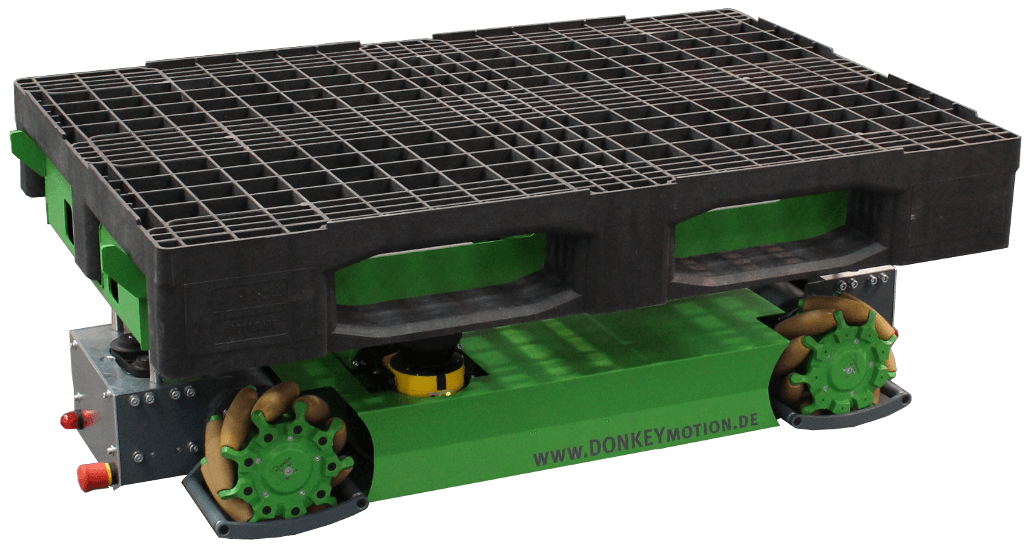

Driverless transport vehicle – THE DONKEY

CALL THE DONKEY is all about the 1,200 mm x 600 mm x 270 mm small DONKEY. The "beast of burden" masters all the typical tasks of intralogistics. For this purpose, it attaches various load modules that enable it to safely transport e.g. Euro pallets, crates, floor rollers or individual goods carriers. In this way, material is moved safely and quickly between, for example, incoming goods, outgoing goods and production cells.

It can be hitched up and unhitched on its own by bending its knees 80 mm, driving under the load modules and picking them up. The DONKEY is not only compact and manoeuvrable, with a payload of up to 1,000 kg it is also an extraordinarily powerful helper.

CALL THE DONKEY – and off we go!

SMART

The "saddlebags" of the load modules carry the batteries and are full of energy! When they are empty, the DONKEY transports them to the charging station to be filled and saddles up a full load module. In this way, it can make full use of its stamina and work around the clock for its client.

SAFE

The DONKEY is intelligent! Because donkeys are not stubborn - donkeys are careful! With its two safety laser scanners, it recognises impending collisions early on and sits out the danger. Balanced and calm, he manages his transport tasks and thus takes the dangerous hustle and bustle out of his factory.

AGILE

Thanks to Mecanum wheels, the DONKEY moves deftly in all directions. You will be amazed at the possibilities this opens up. The automated guided vehicle adapts to your factory, not the other way around! Load transfers, even in confined spaces, are easy to realise.

EASY

The DONKEY orients itself by laser navigation.

You want the DONKEY to travel to new destinations? No problem!

With laser navigation, we offer you a sophisticated high-end technology. The orientation is based on the natural environment; the use of reflectors is usually not necessary. The mapping algorithm used is very robust against changes in the environment, so a new mapping of the environment is rarely necessary. A comfortable software with a graphical user interface also enables the user to plan new routes with this solution.

The DONKEY provides the basis of the automated guided vehicle (AGV). The DONKEY carries a wide variety of loads by attaching one of the following load modules. Here, too, we attach great importance to standards. You benefit from flexible availability and proven systems.

Modules for a wide range of transport tasks

Large load carrier and Euro pallet

Europool palettes (colloquial „Euro palettes") and skeleton containers/wire mesh boxes are the most widely used large load carriers. According to estimates, there are about 400 million Euro pallets in circulation in Europe alone (about one pallet for every two inhabitants). Logically, they are used in the entire transport chain - from intralogistics to overseas transport.

With the large load carrier module, the CALL THE DONKEY automated guided vehicle drives under these load carriers from the front or from the side. The load carriers are supported form-fittingly on the load module. The load module contains the Li ion battery and provides the DONKEY with enough energy for many hours of load work.

CALL THE DONKEY is the forward-looking alternative to the milk run. With the large load carrier, we also drive under such large trolleys and transport them flexibly just-in-time.

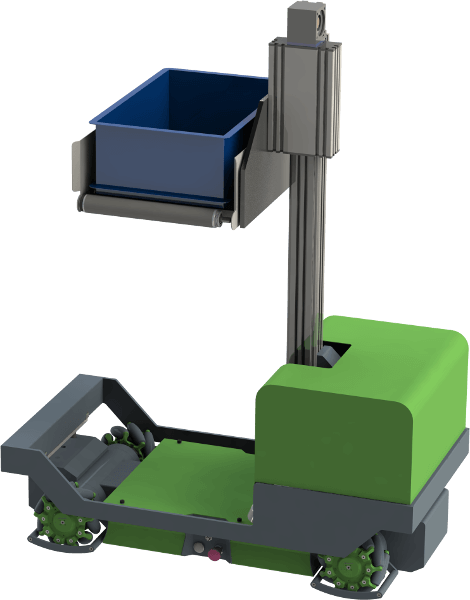

Small load carriers and Euro boxes

Which animal faithfully, diligently and good-naturedly performs all the tasks assigned to it?

Which animal faithfully, diligently and good-naturedly performs all the tasks assigned to it?Small loads are efficiently moved, stored, picked or provided in small load carriers. Common to the different standards for the practical plastic box are the basic dimensions. All common sizes 600 mm x 400 mm, 400 mm x 300 mm and 300 mm x 200 mm are accommodated by the "Small load module". The load transfer is mostly from and to conveyor lines, such as roller conveyors or conveyor tracks.

As the DONKEY stands on stable legs, the small load module can lift the boxes to an ergonomic height of 1050 mm thanks to its large stroke.

The small load module also contains the reliable Li ion battery to supply energy to the automated guided vehicle.

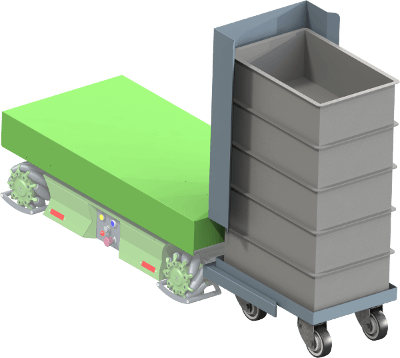

Floor roller

Very lean and smart, floor rollers can be found in many factories today for ergonomic and efficient intralogistics of mesh baskets and plastic boxes (KLTs). Floor rollers are buffered in "stations" in the production cells. The DONKEY saddles up floor rollers loaded with this load module up to 120 kg and saves the time-consuming transports from station to station. Within the production cells, the floor rollers can still be moved ergonomically by hand.

Chip basket

You can't make an omelette without breaking eggs. Or - Where there's planing, there's swarf. We have developed the chip basket load module. This way, the CALL THE DONKEY automated guided vehicle system also takes care of chip disposal in metal-cutting production. The DONKEY carries empty and full baskets in two holders. This allows it to change the basket under the chip ejector quickly and without interrupting production. The full baskets are fed into the centrifuge sorted by type.

Charging station incl. master computer

This base station is the charging station for the load modules. The universal charging technology masters the charging of the different battery technologies in the load modules.

The FIRST charging station already contains the master computer. This makes the commissioning of your CALL THE DONKEY system child's play and is completed in just a few hours. The charging station+ and the other charging stations (without master computer) take up hardly more space than a Euro pallet.

Master controller

The master controller takes care of fleet management (order dispatching), traffic control, route optimisation, parking and battery management. Operators use portable clients to access the web server of the control system to initialise transport orders. Future-proof thanks to the CALL THE DONKEY system, as the production of complex transport operations is automated.

The control system offers extensive "machine-to-machine interfaces". Intelligent production, because CALL THE DONKEY communicates with products, production machines or PPS systems.

Basic set

So what do you need to introduce the LEAN LOGISTICS revolution in your company with the CALL THE DONKEY AGV? Why not start with our basic set?

- 1 pc. Driverless transport vehicle DONKEY-S-1206-Lasernav

- 2 pcs. Load modules

- 1 pc. Charging station +

- Support and maintenance contract over 2 years