Mecanum Wheel: Movement as if on a Cushion of Air With Full Grip on the Ground

The History of the Mecanum Wheel

The Mecanum wheel was invented in 1973 by Bengt Ilon, an engineer at the Swedish company Mecanum AB. The wheel is sometimes called the Ilon wheel after him. The US Navy bought Mecanum's patent and initially used the technology exclusively for loading cargo on their ships. It was not until 1997 that the technology became available for commercial companies and civilian use. So far, most Mecanum vehicles - similar to those used by the Navy - have been used to transport very heavy loads in confined spaces. In the aerospace industry, for example, multiwheeled Mecanum heavy haulers are used to manoeuvre the huge fuselages through the production halls. Smaller Mecanum vehicles are still relatively rare.

The Mecanum wheel was invented in 1973 by Bengt Ilon, an engineer at the Swedish company Mecanum AB. The wheel is sometimes called the Ilon wheel after him. The US Navy bought Mecanum's patent and initially used the technology exclusively for loading cargo on their ships. It was not until 1997 that the technology became available for commercial companies and civilian use. So far, most Mecanum vehicles - similar to those used by the Navy - have been used to transport very heavy loads in confined spaces. In the aerospace industry, for example, multiwheeled Mecanum heavy haulers are used to manoeuvre the huge fuselages through the production halls. Smaller Mecanum vehicles are still relatively rare.

In Europe, imetron is one of the leading suppliers of Mecanum vehicles with DonkeyMotion and has specialised in such smaller and medium dimensions. The omnidirectional DonkeyMotion transport systems are suitable for virtually all industrial applications. Their unique mobility opens up completely new possibilities for automated guided vehicles (AGV) in intralogistics and applications such as stage technology. With Mecanum technology, transport and logistics will change fundamentally in the coming years.

Tons for Omnidirectional Mobility

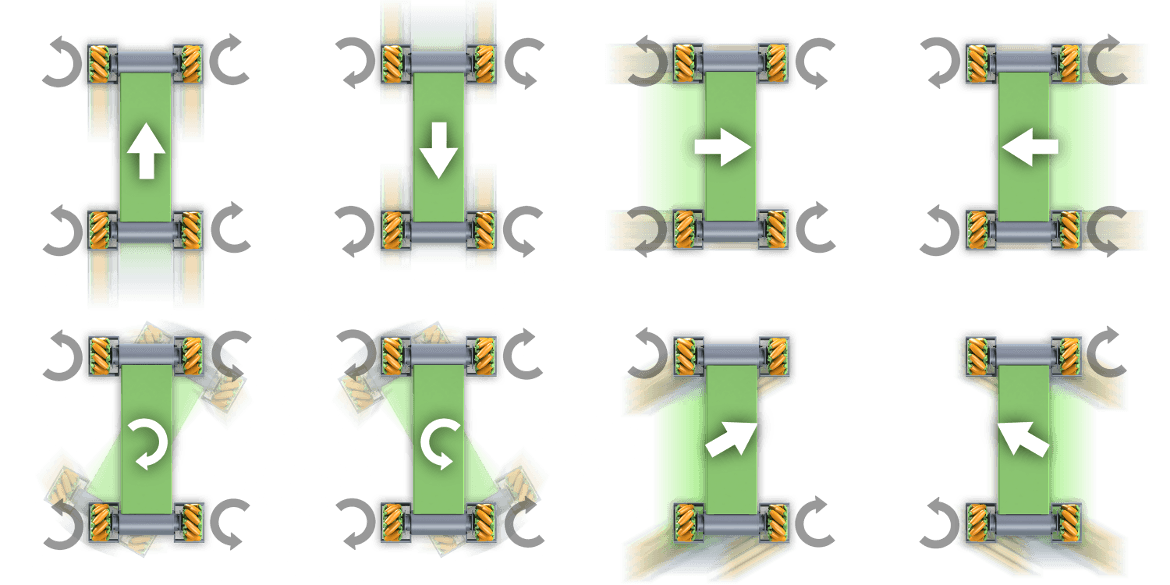

Vehicles on Mecanum wheels can move completely freely in two dimensions - similar to hovercrafts. Both from a standing position and while moving, they can head in any direction, take curves of any radius or turn on the spot. The basis of this omnidirectional mobility is the unique concept of the Mecanum wheel.

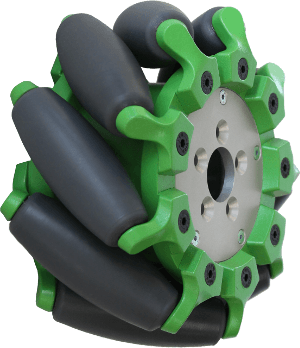

Unlike conventional wheels, the Mecanum wheel does not have a closed tread. Instead, on its wheel rim are rotatably mounted barrel-shaped rollers usually at an angle of 45 degrees to the axis of the wheel. These can rotate freely around their own oblique bearing axis. The shape, size and spacing of the rollers are chosen so that the wheel has a quasi continuous rolling surface.

Power Transmission and Control

When a Mecanum wheel turns, two components of force are created: the first points in the direction of rotation of the entire wheel, the second is at right angles to it. Since its rollers are movable, however, the mecanum wheel is not true to track like its ordinary counterpart. If other forces are added, its movement can be deflected in any direction. In vehicles with four Mecanum wheels, the 45-degree angles of the roller axles are each offset by 90 degrees. By itself, each wheel would move diagonally to a different corner of an imaginary rectangle. You can also imagine the system like a nut on a thread. If you stop the nut from turning, it moves along the axis of the thread. If you let go of the nut, however, it stops and rotates around the axis of the thread.

The direction and strength of the driving force of the individual Mecanum wheel depends on its speed of rotation. The precise combination of the direction and speed of rotation of the individual wheels creates the movement of the vehicle in the desired direction. Among other things, DonkeyMotion vehicles are steered quite simply with a joystick. A small computer (safety PLC) in the vehicle coordinates the movement of the individual Mecanum wheels in order to steer towards the specified target at the desired speed.

And Here is How it Works

For example, to move the vehicle straight ahead, the force vectors of the front wheels must act forward and inward, and those of the rear wheels must act forward and outward with equal force - i.e. speed. In fact, all wheels rotate forward at the same speed, as in a conventional vehicle. If the Mecanum wheels at the front left and rear right turn forwards, and the other two wheels turn backwards, and all at the same speed, it goes sideways to the right. For a curve, all the wheels turn in the same direction, as in a tracked vehicle, but the ones on the outside of the curve turn faster than the ones on the inside. The greater the difference, the tighter the curve.

Mecanum Wheels Need Quality

Running characteristics, energy efficiency and durability of a Mecanum Wheel depend on a multitude of parameters. This includes, among other things, the diameter, width and number of rollers as well as the quality of the materials and individual parts used. The Mecanum wheels of the DonkeyMotion series are regularly further developed and optimised, as well as the variety of control parameters and algorithms of the software. imetron is proud to be as close as possible to the currently achievable optimum in this field.

The smaller the wheel, the more sophisticated its design. imetron is the leading supplier of compact Mecanum Wheels with highest load capacities, long maintenance intervals and best running characteristics. Thanks to the consistent further development of the technology since 2010, imetron can now offer Mecanum wheels that are hard to beat in terms of smooth running and durability. Thanks to a special bearing, they are characterised by virtually vibration-free running. This is also the basis for maximum energy efficiency.

Mission statement:

"imetron is the manufacturer of the most powerful and smoothest running Mecanum wheels in the world."

Mecanum Wheel Creates Free Usable Space

But why the effort? Don't just simple wheels suffice? In many cases they already don't, and in the future of intralogistics this will be less and less the case. Conventional industrial trucks such as pallet trucks require considerable (expensive) manoeuvring areas with their wheel steering systems. These become superfluous thanks to the unlimited two-dimensional manoeuvrability that the Mecanum wheel allows.

A Mecanum transport system does not need much more than a few millimetres distance in order to move between two rows of shelves and do its work there. It can enter the side corridor at right angles from the main corridor without a curve. The width of drive corridors can therefore be drastically reduced and the packing density in warehouses increased accordingly. Material flow and warehouse logistics gain enormously in efficiency. When automating warehouse and production logistics with AGVs, existing halls and production areas no longer need to be converted at great expense.

Ideal for Outstanding Effects as Well as Industry 4.0

Since it can turn on the spot, additional turntables for tool changing carriages or mobile mounting platforms are not necessary anymore. For theatre and entertainment this means the option to use our vehicles as stage wagon and as turntable at the same time. These advantages can also be used effectively in the production logistics of presentation plants ("transparent factory") as well as in showrooms or at trade fair presentations.

In addition to space, time is also saved - just think of the complex process of parking. Instead of driving around finely tuned curves, moving the trolley back and forth until it finally reaches the desired position, a Mecanum vehicle drives next to the gap and at a 90-degree angle directly there, and does so with an accuracy of just a few millimetres. This is an enormous advantage, especially when it comes to fine positioning at load transfer points - for example, a crate rolls from the conveyor track onto a driverless transport vehicle (AGV). The complex computer logic of a computer-assisted marshalling process is also no longer needed. With regard to scenarios such as Industry 4.0 and One Piece Flow manufacturing, the Mecanum wheel therefore offers unbeatable advantages with its simple point-to-point control. Workpieces, parts and production equipment can be transported with maximum flexibility thanks to the Mecanum principle - without any installation or conversion work. The options for automating logistics processes are unlimited.

21st century intralogistics with DonkeyMotion, the smart modular system for Mecanum drives!

Ask us a question. We will be happy to advise you on the selection of our system components (click here for a product overview). Just as you wish, we also realise your complete system. Whether only the planning or the turnkey assembly platform. You decide on the scope of our services!